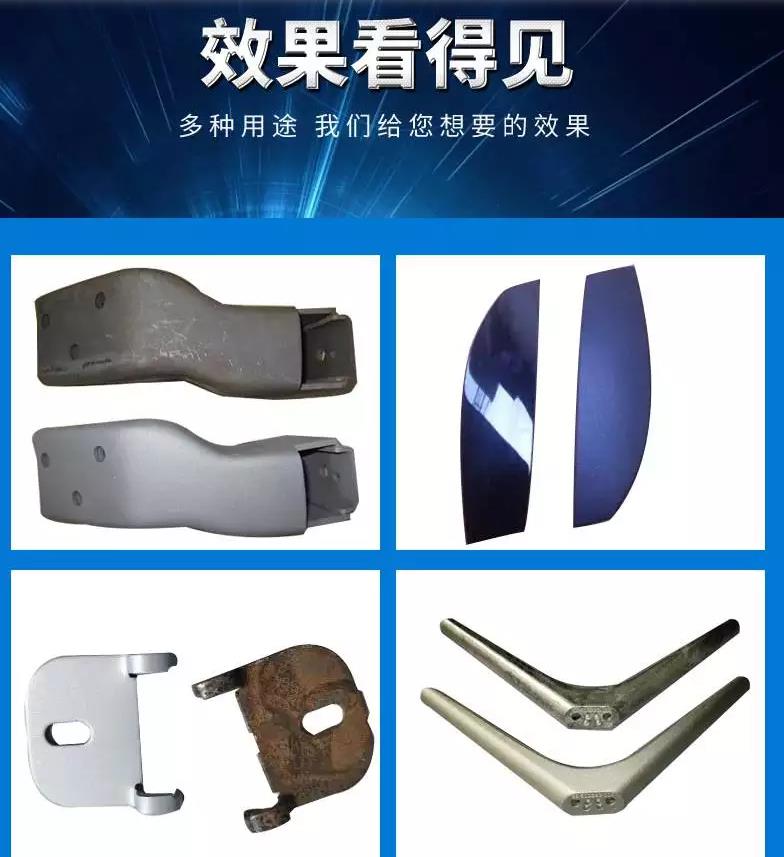

Sandblasting machine model: side door

Dust removal method: pulse filter dust removal

Working cabin size: 900*800*730mm

Overall dimensions: 950*1150*1750mm

Working pressure: 0-8 kg adjustable

Air compressor requirements: 7.5kw

Air pipe connecting air compressor: 3 meters

Fan power: 300W

Lighting: LED dustproof lighting

Thickened cold-rolled steel plate, solid and thick, double protection guaranteed.

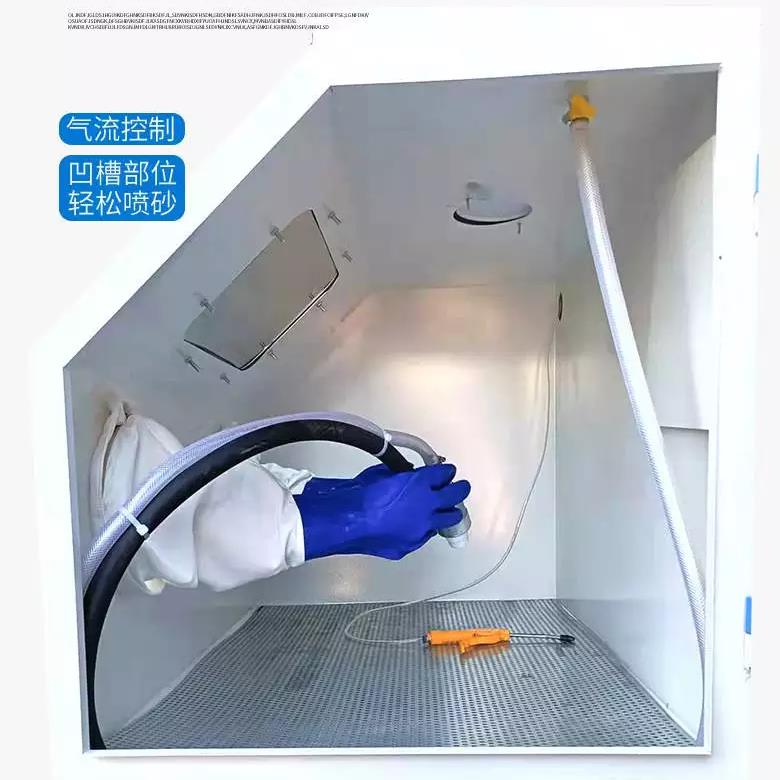

Practical closed sandblasting chamber, built-in professional hollow partition, top energy-saving small lamp, with Montrealaluminum alloy spray gun with boron carbide nozzle, to meet a variety of operating needs.

Pulse dust removal fan, can be timed to remove dust from the dust removal box, free your hands, and increase the life of the dust removal device.

3 micron environmentally friendly filter element, automatic sand return, dust and sand separation, reduce abrasive consumption, sand can be reused.

Wide screen glass panel, embedded glass plate, surrounded by rubber pads, strong sealing; high transparent glass, clear view.

The operating port is connected to rubber gloves, which is simple to use, easy to understand and easy to learn.